Pipe relining is the most cost effective and convenient solution for problem pipes. Feel free to contact Nu Flow today to discuss your pipe problems.

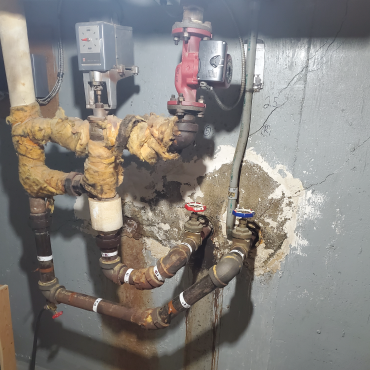

BEFORE

&

AFTER PIPE LINING

WHAT IS PIPE RELINING?

Over the past few decades, advancements in science and engineering have led to the development of cutting-edge and eco-friendly pipe repair methods. The new techniques allow for broken pipes to be fixed from the inside without having to dig.

These methods, referred to as trenchless repairs, CIPP (cured in place pipe) lining, generally involve leaving the old pipes (or what remains of them) in place and inserting a new pipe, made of durable composite epoxy resin, inside of them. This eliminates the need for excavation, digging, or destruction, and provides clients with a more cost-effective and convenient solution for their problematic pipes, while minimizing any negative effects.

WHAT IS CIPP RELINING?

Cured-in-place pipe relining (CIPP) is an effective method for repairing or rehabilitating pipes without the need for excavation or disruption to the surrounding area. This process involves inserting a liner made of advanced composite materials, such as resin, into the damaged pipe. The liner is shaped to fit the interior of the pipe and is then cured in place to form a seamless, rock-hard repair.

CIPP is suitable for a variety of pipes, including those carrying rainwater, waste, grey water, and chemicals. The liner can also be reinforced with materials, such as fiberglass, to provide structural support and increase the strength of the repair. This makes CIPP an ideal solution for pipes located beneath roads or driveways, where excavation is not an option.

CIPP can be used to repair a variety of pipe damage, including cracks, corrosion, and root intrusion. The process can also improve the flow of the pipe and extend its overall lifespan. This can help to prevent costly and disruptive excavation in the future and reduce the need for frequent repairs.

Overall, CIPP is a cost-effective and efficient solution for repairing or rehabilitating pipes without the need for excavation. It can save time and money while reducing disruption to the surrounding area and improving the overall performance of the pipes.

THE BENEFITS OF PIPE RELINING

TRENCHLESS PIPE REPAIR CIPP RELINING CAN:

NU FLOW’S PIPE RELINING METHODS

One of the most popular ways of repairing or rehabilitating pipes without digging is CIPP (cured-in-place) pipe relining. Put simply, advanced composite epoxy resin materials are inserted into failing pipes to repair damage, improve flow, and extend the life of the pipe. For pipes needing structural strength (i.e. beneath roads or driveways) a liner impregnated with epoxy resins is pushed or pulled into the pipe to cure, forming a new pipe lining that will keep it operating successfully for years to come.

These structural and non-structural relining processes are suitable for pipes carrying waste, storm water, rain, chemical (trade) applications and industrial applications.

Our pipe relining methods are tailored to suit each unique repair, and vary depending upon the type of pipe, the climate, other environmental conditions, the operational needs of the client and the built structures or services in the immediate area.

We use CCTV camera equipment to locate the issue, then we use highly specialized tools to clear the pipes and prepare them for relining.

NU DRAIN IS SUITED TO A WIDE RANGE OF PIPING SYSTEMS, INCLUDING:

Mains, horizontal laterals, vertical stacks, sanitary systems, storm/roof drains, vent systems, processed/industrial/chemical piping, other waste systems, residential & commercial properties, industrial, municipal, federal properties, swimming pools

COMMON TYPES OF PIPE THAT CAN BE REPAIRED INCLUDE:

Clay, concrete, metal, iron, cast, steel, PVC, fiberglass. We will look at all types of pipes and try to develop a solution for every unique scenario

COMMON PIPE PROBLEMS WE REPAIR INCLUDE:

Tree root intrusion, bottom gone, mis-aligned, offsets, water intrusion, missing pipe, broken pipe, partially collapsed pipe

Checkout Our Video

CIPP PIPE LINING

Utilizing cutting-edge technology, trenchless sewer repair has never been easier. With trenchless sewer repair, the need for digging trenches is eliminated, all that is needed is an access point hole to allow for equipment.

Repairing or replacing sewer pipes is already a headache and an inconvenience that you have to worry about. Make the process easy and cost effective by using NuFlow’s technology that accesses the sewer system through one or two entrance points. The best part is that your business or family can go about their daily routine with little to no disruption. In addition to saving time and money, trenchless sewer repair prolongs the life of your system, eliminates costly backups and improves water flow since pipes are lined with our patented, environmentally friendly epoxy that stands up to the challenge of everyday use. We are proud to offer these techniques while not disturbing plants, trees, or bushes that can be habitat for wildlife.

Our Latest Projects

Mega Yacht Fire Pipe

View project

Tree Roots House Sewer

View project

High Voltage Duct Lining

View project

Whitehorse Int. Airport

View project

2″ Under Road Heating Pipes

View project

6″ Spa Pool Leak

View projectBroken pipes, tree roots, offset pipes, bottom gone, corroded pipes

Quick and Reliable Repairs ofSewer lines -- storm lines

604-629-9222About Us

Our Certified CIPP Lining Technicians Benefit You:

Examples of Applicable Pipe Systems

Nu Flow's trenchless nu-drain epoxy lining (CIPP) allows us to restore and Re-Nu aged, corroded piping systems to a “better than new” condition without removing them

TYPICAL TYPES OF PIPE PROBLEMS WE SEE EVERYDAY

Another advantage of CIPP is its flexibility in terms of pipe size and shape. The liner can be customized to fit any size or shape of pipe, making it an ideal solution for pipes with unique dimensions. This also helps to ensure a tight, secure fit that provides a long-lasting repair.

In addition, CIPP is a green and environmentally-friendly solution as it minimizes excavation and reduces the amount of waste generated during the repair process. It also eliminates the need for heavy machinery and excavation equipment, which can cause damage to the surrounding environment and infrastructure.

The process of CIPP is relatively quick and efficient, with most repairs completed within a day or two. This helps to reduce downtime and minimize disruptions to the normal flow of water and waste through the pipes. Additionally, the cured liner forms a smooth, seamless surface inside the pipe, which helps to reduce turbulence and increase flow efficiency.

In conclusion, CIPP is a reliable and cost-effective solution for repairing or rehabilitating pipes. It offers a number of benefits over traditional excavation methods, including reduced downtime, minimal disruption, improved flow, and increased longevity. Whether you are dealing with a small crack or a large-scale problem, CIPP is a versatile and effective solution for all types of pipe repair needs.