Spray Epoxy Coating

Fire Suppression Pipe

Situation:

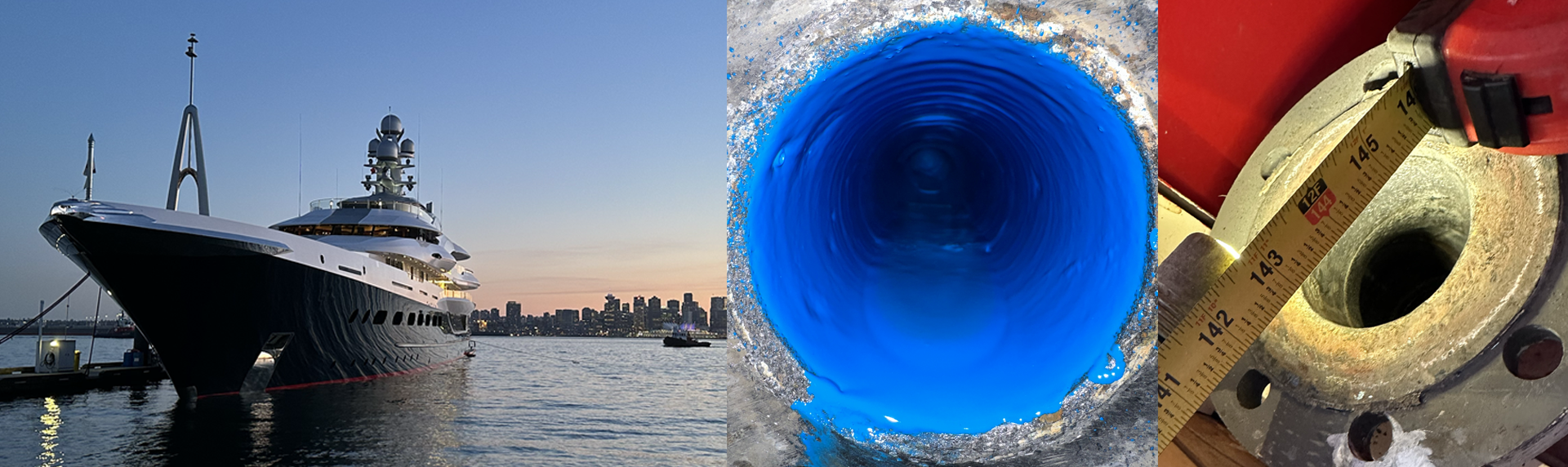

Pipe: 80mm, 100mm / 3″, 4″ Fire Suppression Line

Function: Provide water to hydrant locations around the ship

Pipe Location: Various locations throughout the ship

Problem: Salt water is pumped from the ocean through the pipe to various fire hydrants throughout the ship. After years of sitting in the pipe, the salt water has started to cause pin holes in the thick steel. These pinholes cause incredible amounts of damage to the interiors that are custom made for each area. Almost all the time the pipe is concealed. behind walls, under floors, behind large equipment. As well every piece of the steal pipe on the ship was hand made to fit it’s location perfectly. To replace a section of pipe meant for a major deconstruction of a wall or floor or ceiling and custom fabrication of a new piece of pipe.

Solution:

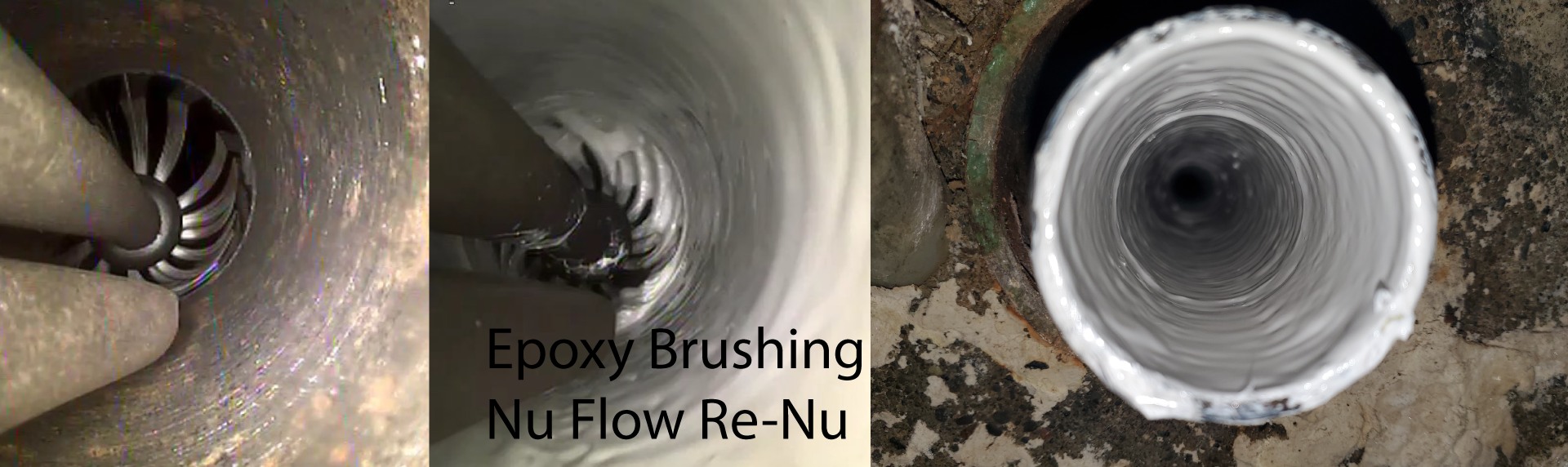

Working with the engineers of the ship. The engineers drained the system, and opened up the pipes at various locations throughout the ship. From these access points we were able to use our specialized cleaning tools to bring the steel pipe up to paint ready finish. From threw we are able to install our liners in sections that were accessible to our lining equipment and use our spray system to spray epoxy in pipes beyond multiple 90 degree bends and places that liners just would not be able to be used.. By applying liners and a thick coat of epoxy we were able to seal up the pipe preventing the salt water from coming in contact with the pipe in those areas.

Using this innovating technology we were able to save the customer from the incredible costs of taking the walls, and floors apart on this mega yacht.

Spray Epoxy Pipe Solutions

Utilizing the technology of spraying epoxy into pipes has allowed us to fix pipes that are just not accessible to lining. The small spray head technology allows us to visually apply greater amounts in a problem area.

Applications for spray epoxy is swimming pool pipes, sewer pipes, drain pipes and many more.

Feel free to contact us today if you are having problems with your pipes.

Pipe ining is the most cost effective and convenient solution for problem pipes. Feel free to contact Nu Flow today to discuss your pipe problems.